How To Choose The Right Joist Hanger

How To Choose The Right Joist Hanger

- Mini Joist hangers,

- Long Leg Joist hangers,

- Face Fix Joist hangers,

- I-Joist hangers,

- Concealed Flange Joist Hangers,

- Saddle Joist Hangers,

- Masonry Joist hangers,

- Welded Masonry Joist Hangers,

- Masonry Return Joist Hangers.

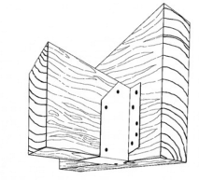

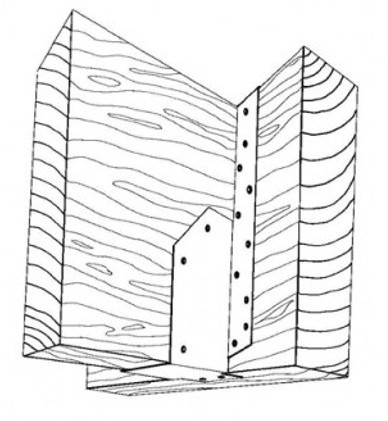

Timber to Timber Joist Hangers

Timber to timber joist hangers are used, where you need to strengthen a load bearing or non-load bearing timber connection. These joist hangers use face mount attachments to fasten joists to ledger boards and beams. They could be named as face-fix joist hangers.

Advantages

- A simple, fast effective way to fasten joists to the face of beams, ledger boards,

- Fast and reliable fixing method,

- Simple nail fixing,

- No drilling required.

Mini Joist Hangers

Mini joist hangers are used for light duty applications such as trimmers, ceiling joists, decking, studs and smaller timbers. Mini joist hangers are generally used for widths up to 78mm and depths up to 100mm.

Mini Mini Joist Hanger Multifunctional Mini Joist Hanger Woody Mini Joist Hanger

Long Leg Joist Hangers

The long legged joist hangers are used when floors are being constructed at different levels to each other. The legs can be freely bent over to accommodate different depths. Depending on the length of the leg, the joist hanger maybe considered long - 450mm to 600mm, standard - 300mm and short - up to 210mm. The boot usually have a tag that can significantly contribute to faster and more accurate fixingand to avoid unnecessary rotation. If necessary, this tag can be easily bent. There are also joist hangers without tags.

Short Leg Standard Long Leg No Tag

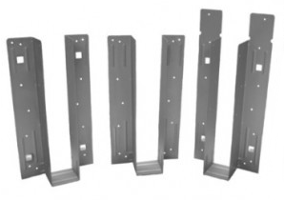

Heavy Duty Joist Hangers

The heavy duty joist hangers are face-fix type and are designed for applications where additional strength is required or where access to the top of the timber or steel is not available. They can be either nailed or bolted. They should be hung minimum of 60% of supported member to avoid rotation. These heavy duty hangers can support heavily loaded timber beams or two ply trusses on supporting timber beams or girder trusses.

I-Joist Hangers

These hangers are for fixing I-Joists to the face of timber beams and to ledger boards and are highly cost effective. They have to used full depth to avoid rotational restraint to the I-Joist and to ensure the correct structural performance. They are engineered to combine maximum load carrying capacity with easy hands free site installation. They are available either face fix or top fix variations. Some of them have locators for easy fixing.

Installation Instructions

Advantages

- For connecting joists to masonry and supporting beams,

- Build into new brick or blockwork,

- For extensions and renovation work,

- Eliminate the need to build around joists or cut holes in facing brick work,

- Can be used for timber to timber applications

Types of Masonry Joist Hangers

- Single Piece Joist Hanger,

- Welded Masonry Joist Hanger,

- Welded Masonry Return Joist Hanger,

- Return Joist Hanger with Adjustable Lock Plates,

- Straddle Welded Joist Hanger

The Single Piece Joist hanger and the Welded Masonry Joist hanger are the traditionally used joist hangers in construction. The back plate of the hanger should lie flat against the vertical masonry support and the flange of the hanger is placed in a dry slot. At least a minimum of 3 courses bricks (675mm) laid above the flange. The masonry is then allowed to mature before any load is applied.

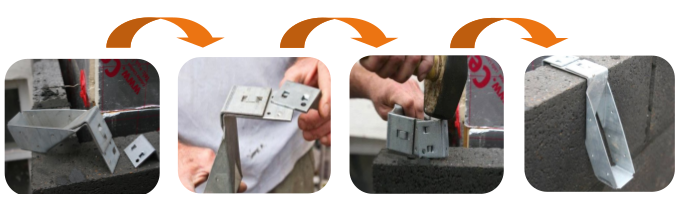

It is possible to use a lock plate to transform the above masonry hangers work as return masonry hangers. such lock plates can be bought separately. This plate is easily be transformed into a hook over joist hanger. No special tools or rivets are required. Just insert Lock Plate at 90, rotate and tap into place.

Welded Masonry Return Joist Hangers are availble in two categories; hanger with fixed return and the hanger with adjustable return plate. The Masonry Return Joist Hangers are designed for similar applications and installation as the standard Masonry Joist Hangers. The return adds additional lateral support by wrapping around the back of the masonry or timber. They have a 25mm drop on the return flange as standard.

Hanger with a fixed return Hanger with an adjustable return

How to install masonry joist hanger with an adjustable lock plate.

Straddle Joist Hanger is actually two hangers joined together by a plate on the masonry flange to enable exact alignment of two joists positioned directly opposite each other on either side of a wall or beam. This plate can be either fixed or adjustable.