Timber Connectors and Metal Plate Fasteners

Timber Connectors and Metal Plate Fasteners

Timber connectors improve the transfer of loads by increasing the bearing area between the fasteners and the timber.

General Timber Connector types

- Bolted down connectors that draw the members together,

- Metal plate types that allow members to remain in the same plane

There are three types of bolted timber connectors,

- Tooth plate connectors,

- Split ring connectors,

- Shear plate connectors.

Tooth Plate Connectors

Tooth plate connectors are made from cold rolled band steel or hot dipped galvanised mild steel. They are available in a variety of shapes and sizes, with diameters ranging from 38 to 165 mm. Larger connectors are available for use in glued-laminated members. They are mostly circular, but square and oval shapes are also available. The joints are normally held together by bolts installed with round or square washers of a size about half the diameter of the connectors used. They come with one-sided and double-sided toothing.

The tooth plate connectors are used in laterally loaded timber-to-timber and steel-to-timber joints. They are pressed into the timber members to be connected. Double-sided tooth plate connectors are used in timber-to-timber joints; alternatively, pairs of single-sided connectors may be used back-to-back, if the joints should be demountable. Single-sided connectors are also used in steel-to-timber joints. Since the teeth are pressed into the timber, tooth plate connectors can only be used in timber or wood-based panel products with a characteristic density of not more than about 500kg/m3.

Single-sided connector Double-sided connector

First, the bolt hole is drilled in the wood, then the connectors are placed between the timber members and the connection is pressed together. A hydraulic press or a high strength bolt is used as pressing the connector teeth into the timber requires considerable force and either. Only for small connector diameters up to 65 mm, mild steel bolt can be used. If bolts are used to press the connector teeth into the wood, large washers are required, otherwise the chance of crushing of the wood is higher. After pressing, the high strength bolt is replaced by the permanent mild steel bolt using washers. Coach screws may also be used in connection with tooth plates, as an alternative to bolts.

In single-sided tooth plate connections, the load is transferred by shear in the bolt. In a double-sided tooth plate connector joint the load is transferred from one timber member to the other through embedding stresses into the teeth of the connector and through the plate, into the teeth on the opposite side. In single-sided connections, the hole diameter in the tooth plate corresponds to the bolt diameter plus a small tolerance. Due to this tolerance, a larger initial slip can be expected in single-sided connections.

- Single-sided and double-sided tooth plate connectors transfer the load directly between the surfaces of the members that are in contact.

- Double-sided tooth plate connector joints are used in laterally loaded timber-to-timber connections, whilst single-sided tooth plate connector joints can be used in steel-to-timber connections and in demountable timber-to-timber joints.

- Connector and timber dimensions, as well as the load-carrying capacity of the bolt are the primary influences on the connection strength.

- Connection stiffness depends mainly on connector diameter and the timber density.

- Tooth plate connector joints cannot easily be used for timbers with a characteristic density of more than about 500kg/m3.

Split Rings and Shear Plates

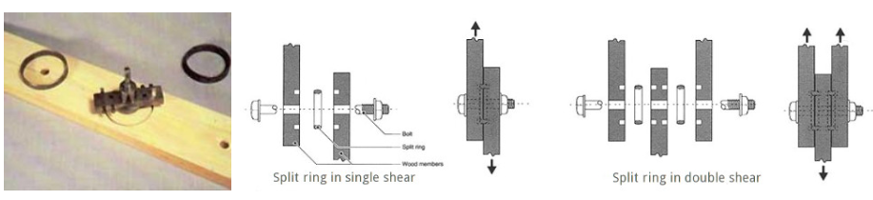

Split rings and shear plates are formed from steel, aluminium cast alloy, cast iron, zinc plated, galvanised steel and stainless steel. Diameters vary from 60 to 260 mm. They are circular and are placed in pre-cut grooves produced by rotary cutters. Split ring connector units consist of one split-ring with bolt, washers and nut. The split ring may be of parallel or bevel-sided form. The bevel-sided form is claimed to be easier to insert and to give greater load capacity.

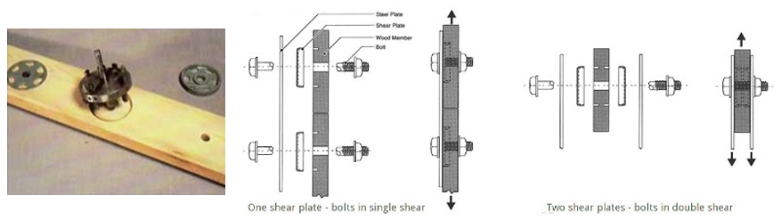

Split ring and shear-plate connectors are used in laterally loaded timber-to-timber and steel-to-timber joints. Split ring connectors are exclusively applied in timber-to-timber joints, whilst shear-plate connectors may be used for steel-to-timber as well. Shear-plate connectors are normally installed before the assembly of the structure. These joints are demountable.

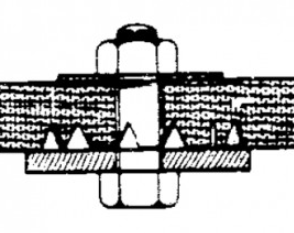

The Ring is split across at one point, the split being in the form of a tongue and groove. The purpose of the tongue and groove is to provide for possible expansion or contraction of the timber. When the ring is embedded in the timber, it can expand or contract with the wood, and thus at all times forms a tight and rigid connection. The ring is sunk into the groove of one of the two facing members, and the other half into the groove of the other member, so that when the two members are joined face to face, the ring is wholly embedded between them. The bolt principally serves the purpose of holding two members together.

Shear plates are intended primarily for wood-to-steel connections or for wood-to-wood connections in demountable structures when used in pairs. Shear plates provide greater load-carrying capacity in shear than can be achieved by a bolt alone. Shear plate timber connectors are used for increasing the strength of the joints in timber construction and reduce the number of bolts required. The face of the shear plate inserted to be flush with the surface of the timber.

First, the bolt hole and the connector groove are drilled into the wood. The cutters used to make the grooves should correspond to the shape of the ring cross-section. Then, the connectors are placed into the grooves and the timber members to be connected are put together. Finally, the bolts are inserted into the holes and tightened. Alternatively, coach screws may be used to hold the connection together.

Precision in grooving and boring is essential for the correct installation and satisfactory performance of these types of connector.The load in a split ring connector joint is transferred from one timber member to another through embedding stresses via the ring connector. In shear plate connections, after the transfer of the load into the connector, the bolt is loaded through bearing stresses between the shear plate and the bolt, and the load is transferred through the shear resistance of the bolt. Then, the second shear plate or a steel member is loaded by the bolt. In shear plate connections the hole diameter in the shear plate consequently corresponds to the bolt diameter plus a small tolerance, an initial slip can be expected in shear-plate connections.

- Split ring connector joints are used in laterally loaded timber-to-timber connections, whilst shear plate connector joints can also be applied in steel-to-timber connections.

- Timber and connector dimensions, spacing, end distances and density are the primary influences on the connection strength.

- Connection stiffness depends mainly on the connector diameter and the timber density.

Metal Plate Fasteners

- Punched out Metal Plate Fasteners,

- Nail Plates

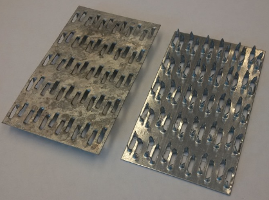

A Metal Plate Fastener is a punched metal plate is as a fastener made of metal plate, having integral projections punched out in one direction and bent perpendicular to the base of the plate, being used to join two or more pieces of timber of the same thickness, in the same plane. They are generally manufactured from pre-galvanised mild steel strip or stainless steel strips, with thicknesses ranging from 0.9 to 2.5 mm. They are widely used for light-framed timber trussed rafters and also for in-plane joints in other components. Punched metal plate fasteners are usually used in factory prefabrication. They able to transfer member forces with smaller connection areas than are possible with hand-nailed plates.

Nail Plates

Nail plates are usually manufactured from galvanized mild steel and stainless steel, capable of receiving hand placed nails. The typical thickness is 1 mm, with pre-formed holes for nails. It is recommended the use of improved nails, such as square twisted nails. The nails should be a tight driving fit in the plate holes. They are also used to repair timber. The plate has strengthening ribs for added rigidity. All holes are pressed countersunk to aid location of the nail and to give a flush finish.